The nitrification process has strong dangerous characteristics

(1) The reaction speed is fast and the heat is large. Most nitration reactions are carried out in heterogeneous phases, and the uneven distribution of reaction components can easily cause local overheating and lead to danger. Especially at the beginning of the nitrification reaction, it is very dangerous to stop stirring or to cause stirring failure due to the falling off of stirring blades. Once stirring is started again, it will suddenly cause local violent reaction, instantly release a lot of heat, causing explosion accidents;

(2) The reaction material has the risk of ignition and explosion;

(3) nitrification agent has strong corrosion, strong oxidation, and oil, organic compounds (especially unsaturated organic compounds) contact can cause combustion or explosion;

(4) Nitration products and by-products have explosive risk.

Figure 2. Corroded equipment

In view of these dangerous characteristics of the nitrification reaction, it is necessary to strictly control the process parameters during the reaction process, and strengthen the corrosion resistance and corrosion resistance of the equipment of the nitrification reaction. Nitric acid, sulfuric acid, waste acid, intermediate materials have a certain corrosion, especially mixed acid, waste acid and intermediate materials, corrosion resistance requirements are higher. If improper material selection or the use of inferior materials, easy to cause the reactor, jacket leakage, agitator off, reaction temperature out of control and cause accidents.

Figure 3. Explosion of nitrification unit in Jilin Petrochemical Biphenyl Plant

Application advantage of tantalum in nitration reaction

(1) Chemical properties of tantalum metal

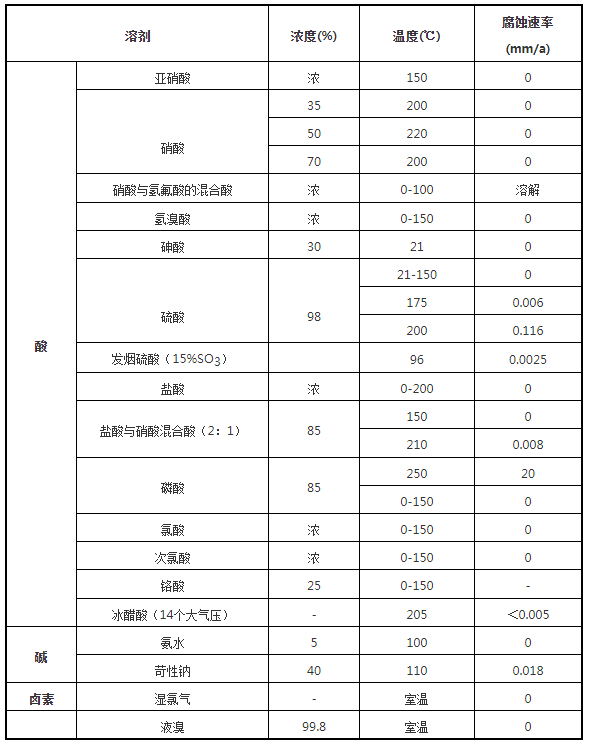

The metal tantalum (Ta) has very excellent chemical properties and has very high corrosion resistance. It does not react to hydrochloric acid, concentrated nitric acid and aqua regia under either hot or cold conditions. Tantalum is immersed in sulfuric acid at 200℃ for one year, and the surface damage is only 0.006 mm. Experiments have proved that tantalum is ineffective to alkali solution, chlorine gas, bromine water, dilute sulfuric acid and many other agents at room temperature, and only reacts under the action of hydrofluoric acid and hot concentrated sulfuric acid. Such a situation is relatively rare in metals.

Table 1 Corrosion rate of tantalum in common media

(2) The application of tantalum in acid equipment

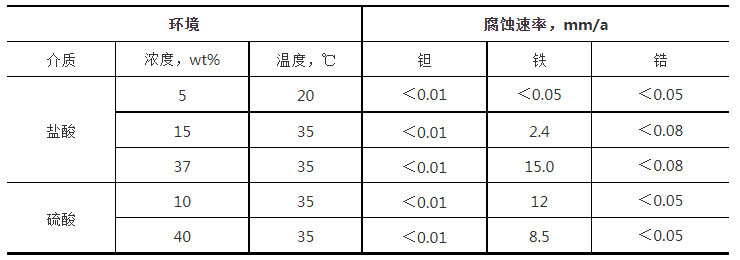

In the production of various inorganic acids equipment, tantalum can be used to replace stainless steel, and the life is dozens of times higher than that of stainless steel. Tantalum is a material selection object for manufacturing equipment for processing hot concentrated sulfuric acid. Because tantalum is of great importance to the sulfuric acid industry, the corrosion rate of tantalum is 0.05ram/a in sulfuric acid with a concentration of 96% and a temperature of 210℃. As far as the acceptable corrosion rate is concerned, the passivation performance of tantalum is still good at 230℃.

Table 2 Corrosion rates of tantalum, iron and zirconium in several environments

(3) Tantalum equipment can ensure the purity of media and products

Another advantage of tantalum equipment is that it can absolutely guarantee the purity of the medium and the product. In this regard, in some industries, especially in the pharmaceutical industry, certain processes have very strict requirements for equipment, and no wear or seepage is allowed to occur even in a strong corrosive environment. In order to meet this requirement, the selection of equipment is very limited. In addition to glass, enamel and silicon cast iron, in all metal materials, only tantalum is the most suitable transition metal.

(4) tantalum plating products to solve the cost problem

The advantages of tantalum metal are needless to say, but as a rare metal, tantalum reserves in the earth are not much, which directly leads to the high price. Due to the limited price, the application of tantalum has been greatly restricted. Ines (Beijing) Tantalum Application Technology Co., Ltd. has been committed to the development of tantalum surface alloy technology for many years, by making tantalum alloy on the surface of ordinary equipment, giving equipment with high performance comparable to pure tantalum products. The emergence of this technology has perfectly solved the cost problem, making the application of tantalum civilian and extensive is no longer a dream.

Sum up

Tantalum has the characteristics, so that its application field is very broad. With the deepening of people's understanding of tantalum metal characteristics, a large number of tantalum materials are used in chemical processing industry, petroleum production industry, pharmaceutical manufacturing industry, food processing industry, metal smelting industry and other corrosion resistant equipment every year.

As an initial investment, tantalum and any tantalum equipment do appear to be higher, but in the evaluation of material selection, in addition to the cost of the material itself, the maintenance, repair and replacement costs of the equipment should also be taken into account. If evaluated from the whole service life, the economy of tantalum is highlighted. Exceptional resistance to corrosion and wear means that tantalum equipment has a longer service life, maintenance and replacement costs (these costs are often many times the cost of equipment acquisition) savings. Coupled with the continuous and stable production process, as well as the maximum reduction of production waste, all reflect the economy of tantalum production equipment.

Now has the strong support of INES tantalum plating technology, so that the industrial production of tantalum plating products is no longer a problem, I believe that with the promotion of this technology, tantalum plating products will be more and more widely used, in the premise of low cost and low input, effectively solve the problem of industrial corrosion.