In fact, the observation that tantalum absorbs acid leads the metal to be named Tantalus.

In clinical use, ductility promotes one-stage cosmetic repair of skull defect. Tantalum became the preferred skull shaping material for more than 1000 operations during World War II.

The history of tantalum cranioplasty can be used as a model of innovative thinking and adaptive technology development.

Autologous cranioplasty

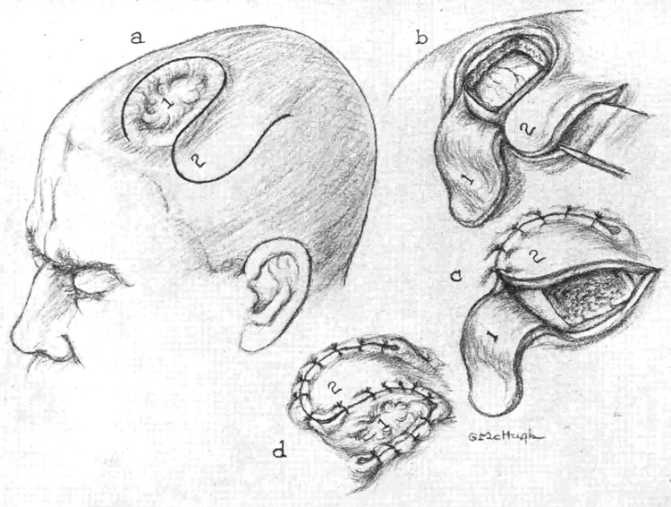

In the mid-19th century, Ollier and Macewen described and popularized the application of autogenous graft in cranioplasty (Figure 1).

Figure 1. a: Make an S-shaped incision around the skull defect (1) to create a second skin flap (2) containing scalp, periosteum and platform. B: Then rotate the flap to cover the skull defect. C: the final appearance after closing. D: The cosmetic effect is generally unsatisfactory.

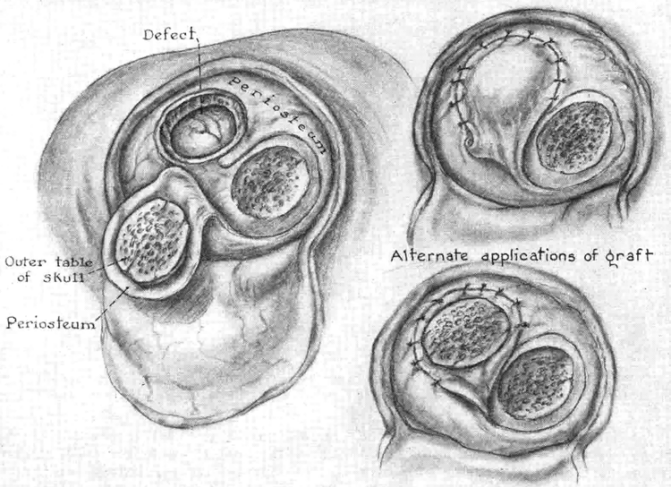

The main disadvantage of this technique is the good cosmetic effect caused by the rotation of the scalp flap and the depression covering the donor site of the external platform. In 1903, von Hacker improved the scalp cosmetology method of Müller König, and only removed the periosteum and external platform from the bone around the skull defect (Figure 2).

Figure 2. von Hacker modification of 2.Müller König technology. Lift a single scalp flap, take out the periosteal graft containing only the external platform from the area adjacent to the skull defect (left), rotate it to the defect and suture it (right).

Many authors tried to obtain free autografts from various sources, such as sternum, scapula, bone, ilium and tibia, long after the local autografts were delivered. Tibial periosteal grafts are the most. Common methods of cranioplasty (Figure 3).

Fig. 3. The periosteal graft of the patient's tibia was placed at the skull defect and sutured with the surrounding periosteum.

Although autogenous cranioplasty is the most common, the increased time, blood loss and the incidence of donor sites have led many people to continue to look for synthetic materials suitable for cranioplasty.

Tantalum cranioplasty

In vivo corrosion of metal implants occurs due to the interruption of vascularized tissues and the existence of new oxygen molecules. Oxidative corrosion of metal implants used in cranioplasty can lead to tissue necrosis, mainly due to the release of metal ions from metal surfaces. Therefore, in order to implant into human body, it seems very important to find a metal that corrodes very slowly or will cause harm to patients.

In a preliminary report in 1940, Burke began to test that organisms achieved inertia by placing metal sheets in a lattice solution at body temperature for 3 months. The appearance and weight of metals and solutions remain unchanged.

The relative inertia of tantalum was confirmed by experimental tantalum cranioplasty on 11 cats. An important discovery in this animal series is the formation of connective tissue capsule around the implant. This was actually considered a significant advantage at that time, because there was no fixed inlay or inlay implantation technology was common. Therefore, the formation of scar tissue can theoretically help prevent implant migration. In all cases, the scar tissue was not compressed and the implant did not interfere with spontaneous bone regeneration.

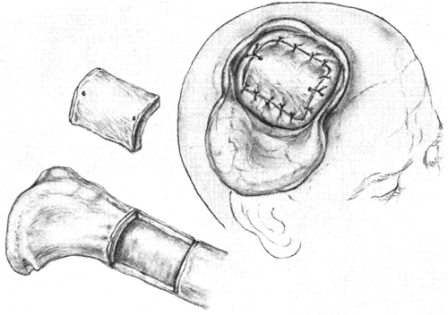

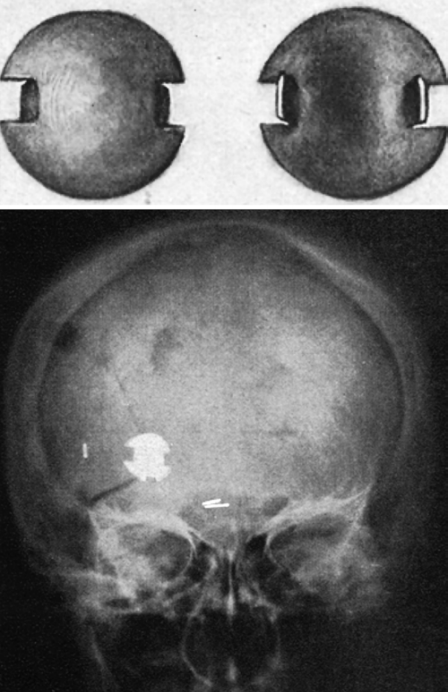

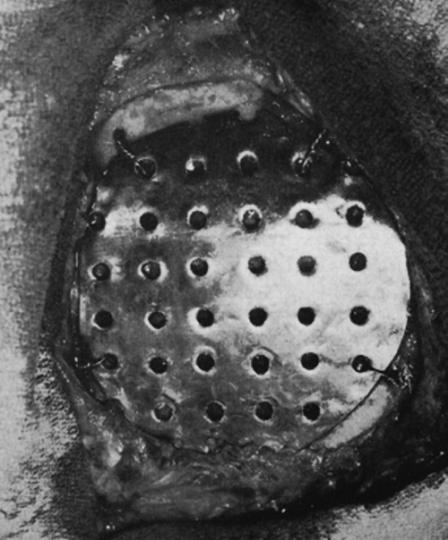

Most importantly, the tantalum implant is intact and has no corrosion. The original tantalum cranioplasty implant consisted of a smooth, non-porous metal plate. The advantage of this design is that it can form a smooth packaging sheath around the board and prevent it from adhering to the underlying cortex or dura mater. This feature makes it easy to remove the implant base when another operation is needed. However, many authors describe several advantages of placing multiple perforations in the plate before implantation. Before the improvement of implant fixation technology, plate migration is a major problem. Perforation promotes the formation of scar tissue between dura mater and cap aponeurosis, which helps to fix the implant.

Figure 4. Upper part: Tantalum disk with label cut to the width of the borehole. Below: postoperative X-ray film, tantalum disk is used to cover the front hole.

Fig. 5. Tantalum plate fixed with Tantalum wire through the perforation on the plate and external workbench.

The extinction and revival of tantalum

Although tantalum was widely used in cranioplasty during World War II, its use in cranioplasty declined sharply in the early 1950s.

Acrylic acid (polymer based on acrylic acid) is the main successor of tantalum used in cranioplasty. The study of acrylic cranioplasty began in the early tantalum age in the early 1940s. Before the war, acrylic resin was used in dental implants and no good tissue reaction was observed. In the decade after World War II, experiments and early clinical reports of acrylic cranioplasty showed promising safety and effectiveness.

However, Spence's report in 1954 clearly proved that acrylic acid was used instead of tantalum in cranioplasty. Spence convincingly described in detail the shortcomings of personal, economic and medical metal plates. First of all, there is a great social shame in having metal in one's mind. Secondly, the manufacturing cost of tantalum is very high.

Polymethyl methacrylate does have its limitations, such as inhibiting bone growth, and some interest in metals still exists. Some authors prefer stainless steel because it is also ductile, but the cost is as low as 1% of the cost of tantalum. Titanium was first used in cranioplasty by Simpson in 1965, and finally became the preferred metal. However, metals such as titanium alloy and stainless steel can cause metal allergy and inflammation in human body.

Ainz Company has developed a vapor-phase tantalum evaporation surface alloy technology to deposit tantalum coating on titanium alloy or stainless steel base to achieve the same effect of pure tantalum.