Tantalum-palladium: non-hysteresis optical hydrogen sensor

Pressure is more than 7 orders of magnitude, sub-second response

Hydrogen is considered as the fuel of green economy in the future. Reliable and cheap hydrogen sensor is an important part of large-scale reconstruction of hydrogen. Hydrogen is a odorless, colorless, tasteless gas, and has great flammability in the air. Therefore, any hydrogen leakage must be detected immediately, which requires efficient, fast, reliable and cost-effective hydrogen sensors. In addition to safe applications, accurate monitoring of hydrogen concentration and pressure is crucial for the efficient and reliable operation of hydrogen fuel cells, CO2 conversion devices and various industrial processes.

Optical metal hydride hydrogen sensor is an attractive candidate material for large-scale implementation of hydrogen economy in the future. Detection of hydrogen in a reliable, rapid and economical manner is a prerequisite for large-scale implementation of hydrogen in a green economy. Thin film Ta1-yPdy is an effective optical sensing material with a very wide sensing range and can cover at least 7 orders of magnitude of hydrogen pressure. The nano-configuration of Ta1-yPdy layer suppresses the first-order phase transition in the body and ensures that the detection response does not have any hysteresis. Unlike other sensing materials, Ta1 - yPdy has special characteristics. It can easily adjust the detection range by changing the Pd concentration without reducing the sensitivity of the detection material. Combined with appropriate coating, the sub-second response time can be achieved even at room temperature, which is faster than any other known thin film hydrogen sensor.

Experiment and Discussion

Optical response

A suitable optical hydrogen sensing material should have monotonous and gradual changes in optical properties over a wide range of hydrogen pressure, independent of the (pressure) history of the sensor. In order to study the behavior of Ta1 yPdy thin film, when a series of steps are applied to increase and decrease the hydrogen pressure at room temperature, we measure the change of white light optical transmittance t relative to the prepared state T prep.

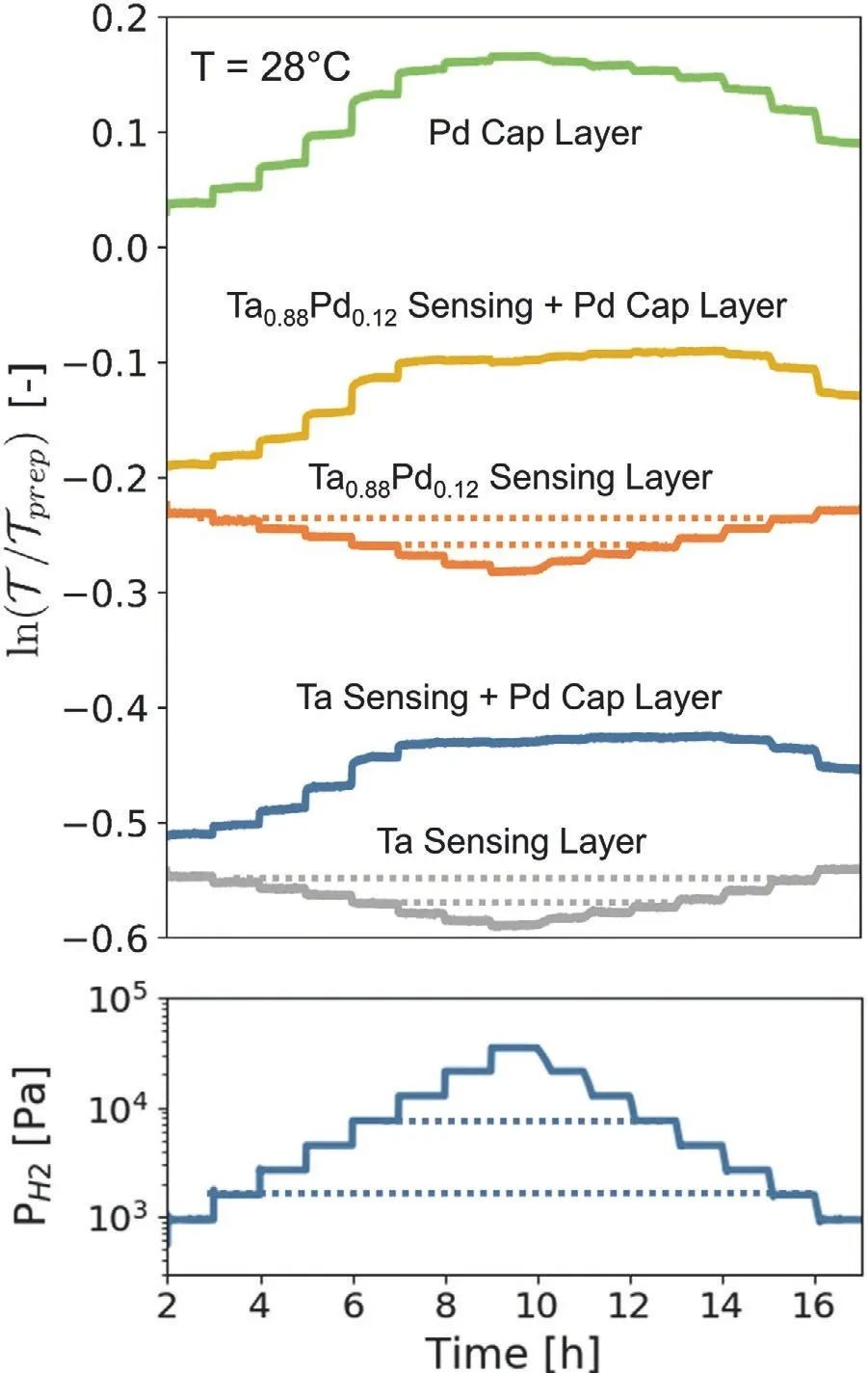

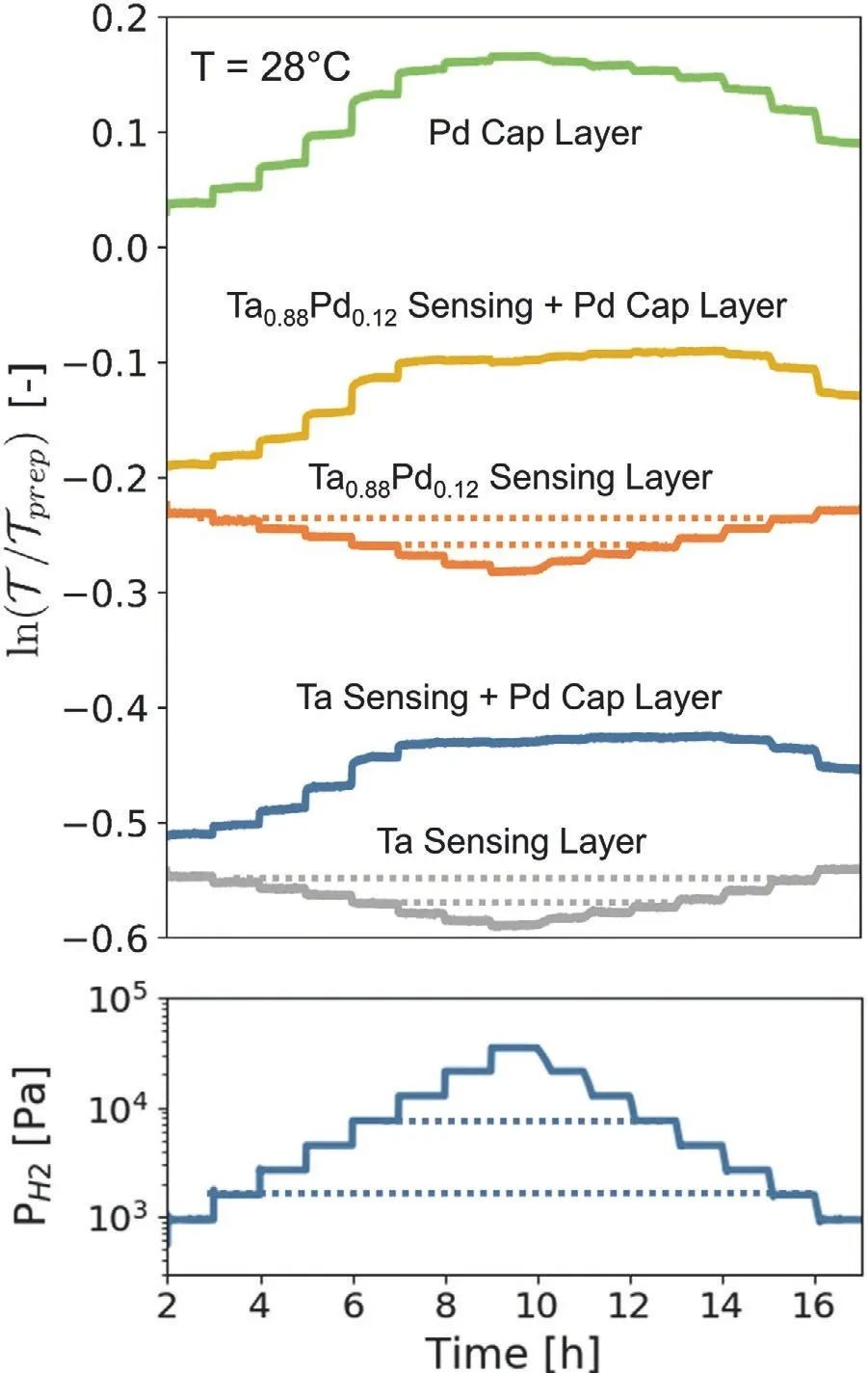

The results of 40 nm Ta and Ta0.88Pd0.12 thin films covered by Pd are shown in Figure 1, and reveal the complex optical response: due to the interference between the optical response of Pd coating and Ta1-yPdy sensing layer, the response of these thin films is highly nonlinear and hysteresis. In order to eliminate the convolution of the response of Pd coating and Ta1 yPdy sensing layer, we subtract the optical response of Ta0.5Pd0.5 film covered by Pd from the target film (Fig. 1).

Figure 1. The change of white light optical transmittance T of Ta and Ta0.88Pd0.12 films with time, both of which are covered with 10 nm Pd and 4 nm Ti adhesive layer, as a function of the transmittance measurement relative to the film so prepared (T prep). It includes not only the response of uncorrected samples, that is, the contribution of the sensing layer and cap layer, but also the response of corrected samples, that is, the contribution of the sensing layer calculated by subtracting the contribution of Pd cap layer from uncorrected samples. The contribution from Pd coating is determined by measuring Ta0.5Pd0.5 film covered by Pd. Ta0.5Pd0.5 does not show any optical response within the studied pressure range, and has adhesion conditions similar to those of Ta1-yPdy of interest, ensuring that the optical response of Pd layer simulates the optical response of the top of the film of interest. At 28 ℃, the membrane is exposed to various increasing and decreasing pressure steps between ph2-1 ´ 10+3-4 ´ 10+4 Pa. The dotted line represents the same level of transmittance (above) and pressure (below).

The optical transmission sensing layer of Ta1 yPdy decreases monotonously with the increase of pressure, which is stable, well-defined and without any lag.

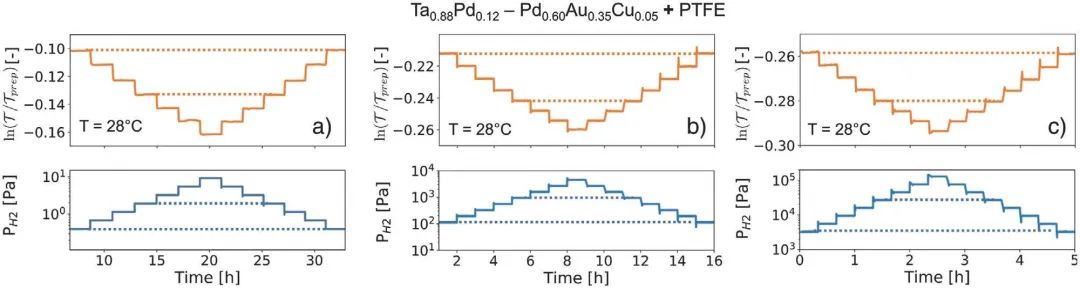

In order to obtain a monotonic response without delay without such deconvolution, we need different covering layers, so we choose Pd0.G0Au0.35Cu0.05.

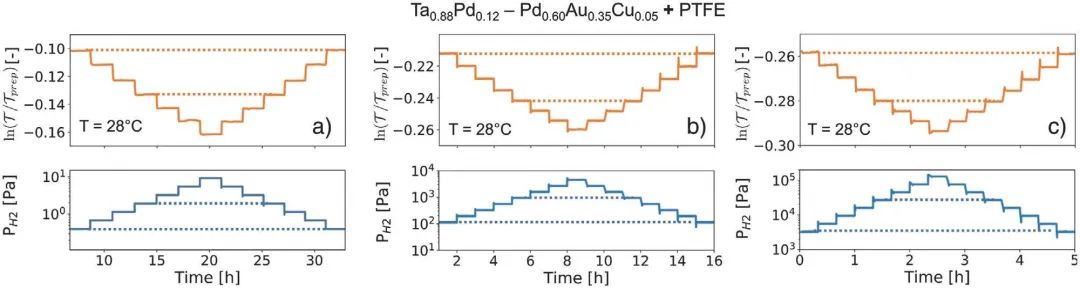

Figure 2 shows the change of white light optical transmittance of Ta0.88Pd0.12 film covered with 10nm Pd0. High 0.35 copper 0.05 in three different pressure areas, ´ 10-1<4.0 Pa,<1.5 Pa, ´ 10+5 1.5 Pa. In all three pressure regions, the light transmission shows a significant monotonic decrease with the increase of pressure. For a given hydrogen partial pressure, the transmission level is clear and stable, and it is important that there is no lag: according to the in-situ XRD measurement, the optical transmission is the same after increasing and decreasing the pressure steps.

Figure 2. Change of white light optical transmittance t of 40 nm Ta0.88Pd0.12 film with 4 nm Ti adhesive layer, which is covered by 10 nm Pd0.60Au0.35Cu0.05 layer covered with 30 nm PTFE layer ("ta 0.88 PD 0.12-PD 0.60 au 0.35 Cu 0.05+PTFE"). The optical transmittance is measured as a function of time and relative to the transmittance of the prepared film (T prep). The membrane is exposed to various increasing and decreasing pressure steps at 28 ℃, a) 4.0 ´ 10-1 £ PH2 £ 9.2 ´ 10+0 Pa, b) 1.2 ´ 10+2 £ PH2 £ 4.5 ´ 10+3 Pa, and c) 3.5 ´ 10+3 £ PH2 £ 1.5 105 pa. The dotted line indicates the level of the same transmission (above) and pressure (below).

Figure 3 shows that all Ta1-yPdy films with y ≲ 0.12, including pure Ta, have excellent optical response without hysteresis and large and almost constant sensitivity within an extremely wide sensing range of at least 7 orders of magnitude of pressure. This makes this material unique, because the known metal hydride, Pd1-yAuy, which has the largest sensing range at room temperature, only has a sensing range of about 4 orders of magnitude.

Figure 3. Hydrogen partial pressure and temperature dependence of the optical transmittance t of the 40 nm Ta1-yPdy sensor layer relative to the optical transmittance measurement in the prepared state (t preparation). Use the same method as Figure 1 to measure. Each data point corresponds to the optical transmission after exposing the film to a constant pressure of ph2 10-1-10+6 pa for at least 1 hour, wherein the closed data point corresponds to the increased pressure step, and the open data point corresponds to the reduced pressure step. Figure a) shows the pressure dependence of different y values in Ta1-yPdy at t 28 ℃. Figures b) and c) show (b) Ta and (c) Ta0.88Pd0.12 at different temperatures. The right axis represents the x in Ta1-yPdyHx based on the scale between the optical response and the hydrogen content of Ta measured using the in-situ neutron reflectometer.

Structure status

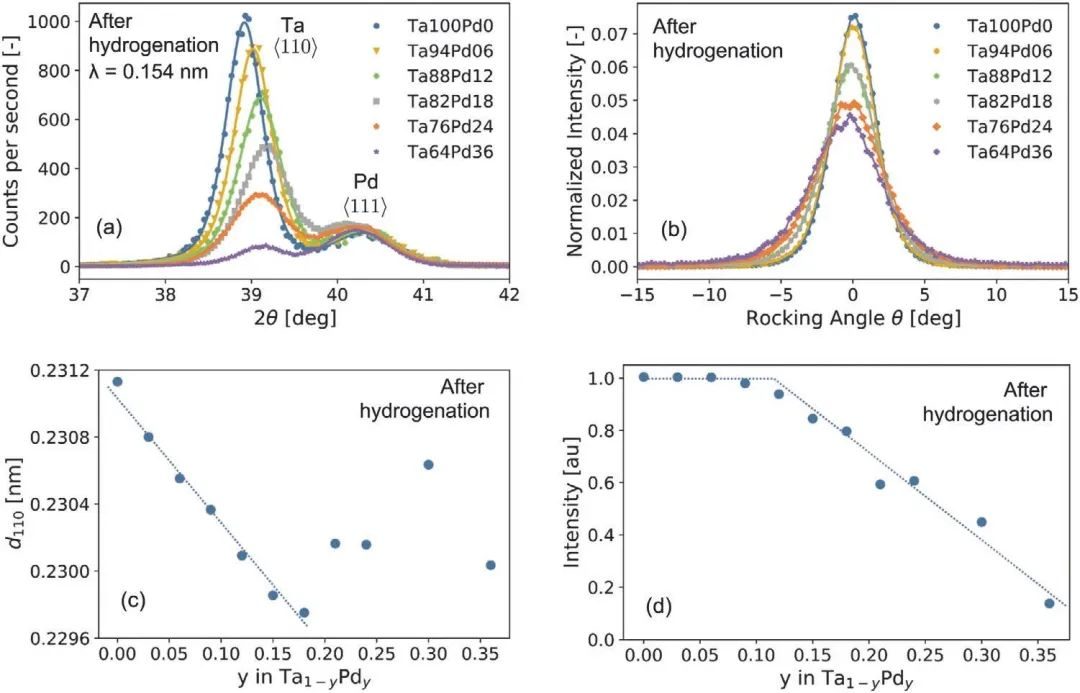

The sensing results of Ta1-yPdy film show that: I) there is no phase separation, so the solid solution of Ta and Pd is formed, and there is no separation during the hydrogenation process, because this will reduce the life and stability of the sensor, and ii) there is no (first-order) phase transition during hydrogenation, because this will lead to a lag response with a long response time.

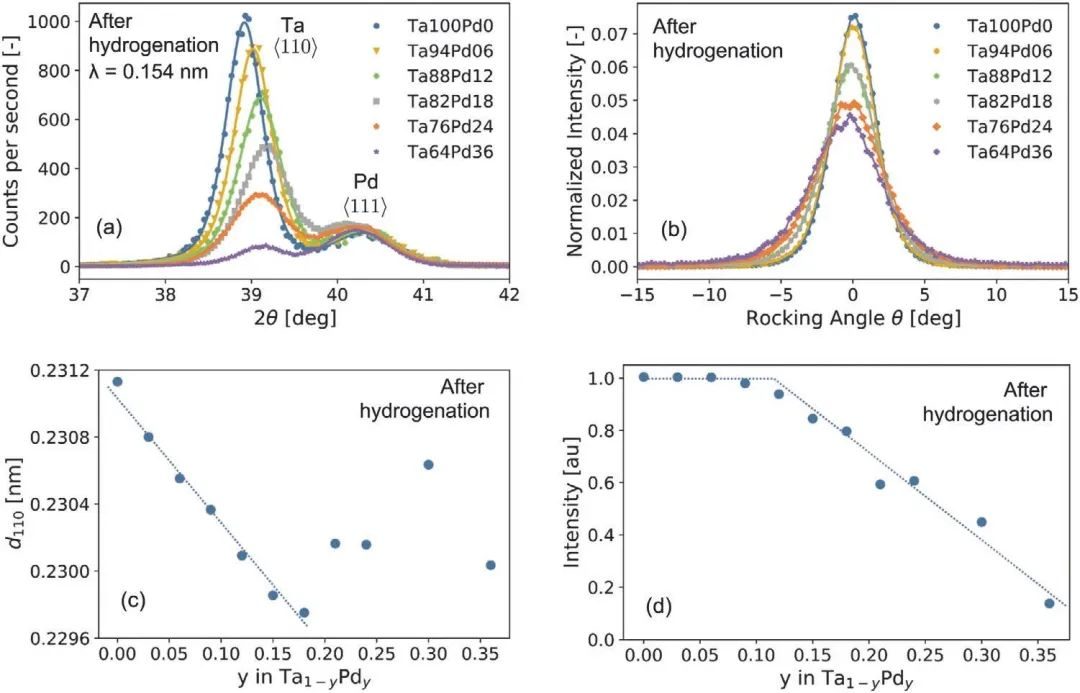

X-ray diffraction (XRD) measurements showed that the formation of Ta1-yPdy film covered by palladium, such as solid solution in bulk, showed no sign of phase separation for y ≲ 0.12. This is true for the newly prepared membrane and the membrane exposed to at least 300 hydrogen cycles. The measurement results are shown in Figure 4.

Figure 4. After the film was exposed to hydrogen and measured in air, the results of in situ x-ray diffraction (XRD) of 40 nm ta1-ypdy film with 4 nm Ti adhesive layer and covered with 10 nm Pd layer. a) Diffraction diagram of ta1-ypdy film (Cu-Kv, λ 0.1542 nm). The solid line represents the fitting of two pseudo Voigt functions to the experimental data. b) Rocking curve of ta1-ypdy film near ta1-ypdy á 110 ñ peak. c) Pd doping dependence of d110 spacing in ta1-ypdy. d) Pd concentration dependence of the total intensity of the á 110 ñ diffraction peak in ta1-ypdy, which combines the influence of the amplitude and width of the change. The strength is proportional to the strength of the Ta sample. The dotted line acts as a guide for the eyes.

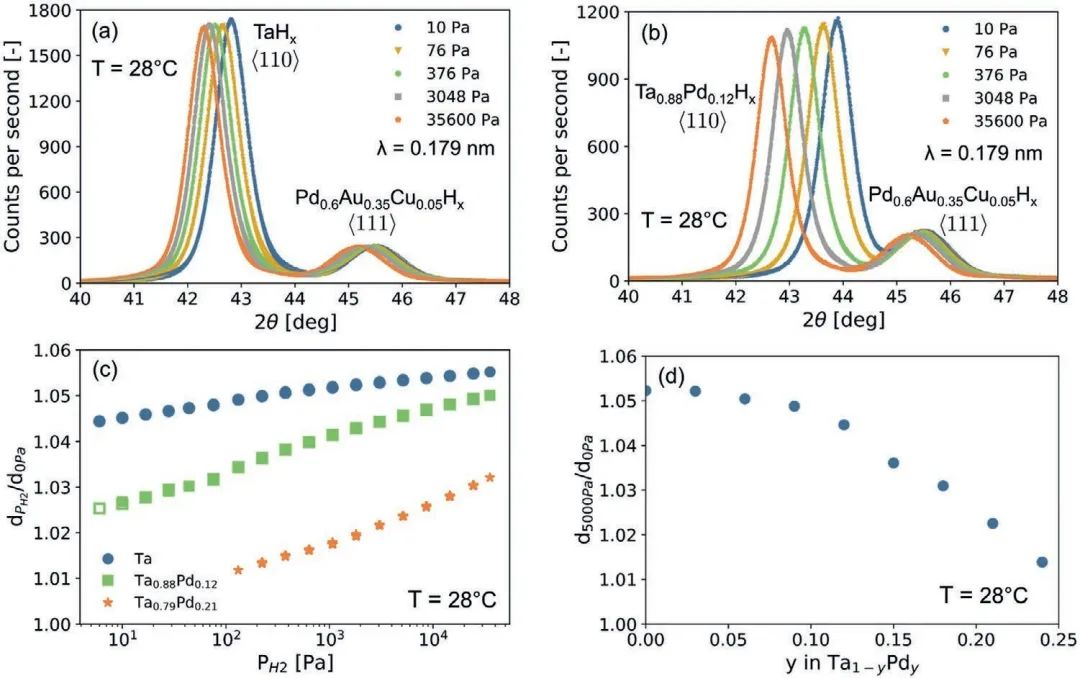

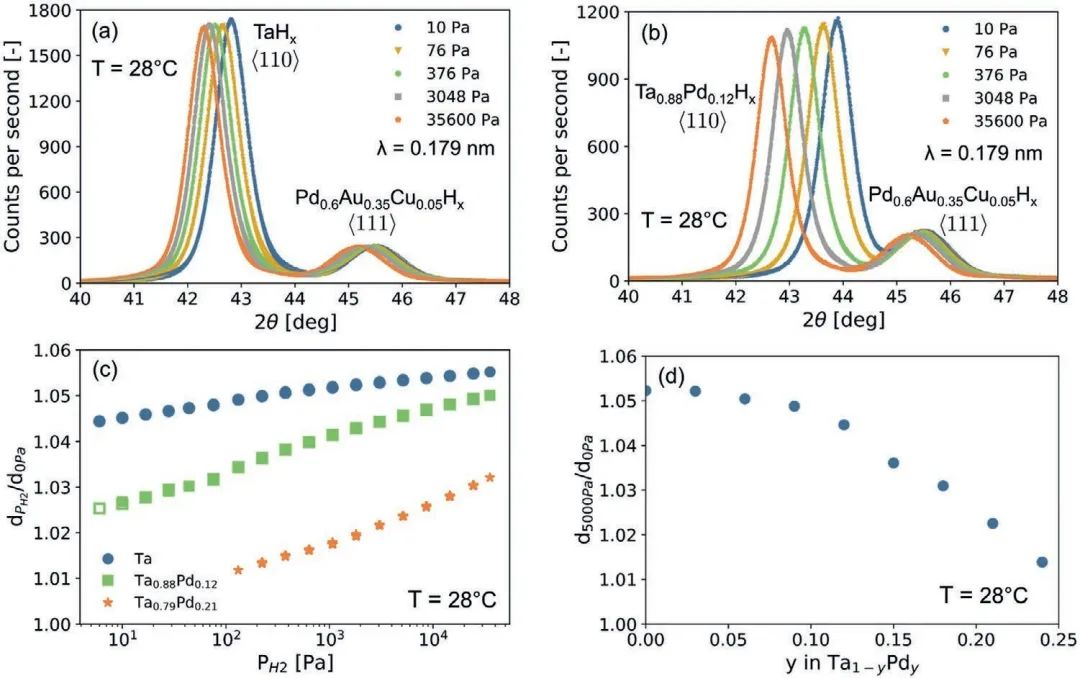

For the nano-sized film, the sensing measurement revealed the non-hysteresis response on the whole pressure window at room temperature, indicating that various phase transitions were suppressed. The in-situ XRD measurement in Figure 5 confirms that the stress leading to plastic deformation is high enough for ta1-ypdy to ignore this situation, and there is no hysteresis of any kind to make ta1-ypdy an attractive material for thin film hydrogen sensing applications.

Fig. 5.40 In situ XRD results of ta1-ypdy film at 40 nm, the film has a 4 nm Ti adhesive layer and is covered with a 10 nm Pd0.6Au0.35Cu0.05 layer, and the 10 nm PD 0.6 au 0.35Cu0.05 layer is covered with a 30 nm PTFE layer for t 28 ℃. Diffraction pattern (co kv) of ta1-ypdy film with a) y 0 and b) y 0.12 λ 0.179nm) for the hydrogen pressure and pressurization steps shown in the legend. The solid line represents the fitting of two pseudo Voigt functions to the experimental data. c) The hydrogen pressure dependence of d110 spacing expansion in ta1-ypdy is relative to the no-load state measured by increasing (closing symbol) and decreasing pressure (opening symbol). d) Doping dependence of d110 spacing expansion measured at ph 2-5.0 ´ 10+3 Pa.

Conclusion

Ta1-ypdy is an effective and universal hydrogen sensing material with a pressure sensing range of at least 7 orders of magnitude at room temperature and high temperature. The nano-constraint of ta1-ypdy layer inhibits a series of first-order phase transitions in the bulk, and ensures that there is no lag in the sensing response in a single thermodynamic phase. The alloy with Pd compresses the crystal cell and effectively adjusts the sensing range without losing the sensor sensitivity. Combined with a properly and reasonably designed coating, it has a sub-second response time at room temperature, which is faster than any reported thin film sensing material. The combination of these short response time, large sensing range and the possibility of cost-effective production paves the way for the large-scale implementation of this material in the sustainable hydrogen power economy.