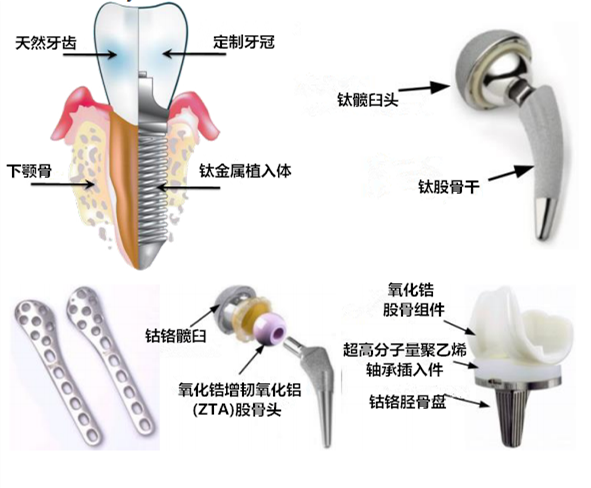

1 Titanium alloy implant

Titanium and its alloy (Ti-6Al-4V) have good biocompatibility and can be used for hip, knee, shoulder and ankle joint replacement. In the long-term application of traditional Ti-6Al-4V implant material. There are some problems, such as the release of harmful ions caused by poor wear resistance, insufficient biological activity and reduced corrosion resistance.

Tantalum (Ta) coating: In 1940, pure tantalum was first used in orthopedics. Subsequent studies showed that metal tantalum did not show any adverse effects as a human implant. Over-plating metal tantalum and its oxide, nitride, etc. can promote cell adhesion, proliferation and differentiation. Li deposited TaC coating on the surface of titanium alloy, and mixed with other atoms to prepare TaCN and TaN coating to adjust the chemical composition. These coatings can promote the early adhesion of cells and make cells grow in a better form on the surface. TaCN and TaN coating can promote cell proliferation. TaC has little effect on osteogenesis, while TaCN and TaN promote the deposition of calcium nodules, up-regulate the secretion of alkaline phosphatase (ALP), and show good osteogenic activity. TaC, TaCN and TaN coatings are expected to be applied in the field of orthopedic implants, especially in the field of surface modification of titanium alloy artificial joint frame. Bao coated the surface of Ti-6Al-4V alloy with nanocrystalline Ta2O5. The coating has a good combination with the substrate, which improves the corrosion resistance, antibacterial property, cell compatibility and blood compatibility of the alloy.

2 Cobalt-chromium alloy implant

Cobalt chromium molybdenum (CoCrMo), commonly used in cobalt-chromium alloy medical devices, has good wear resistance, and ion release is one of the defects that cannot be ignored. Therefore, people have been trying to improve its biocompatibility.

Tantalum (Ta) coating: CoCrMo does not have the bone integration and characteristics required for implant survival. In contrast, tantalum is considered as an excellent biomedical coating because of its good bone conductivity. Halmanna has prepared Ta coating on CoCrMo alloy with a thickness of about 20-600nm. After immersion in simulated body fluid for 4 weeks, a large number of apatite crystals were deposited on the surface of tantalum coated samples, indicating that the biocompatibility of tantalum coated cobalt chromium alloy has been greatly improved.

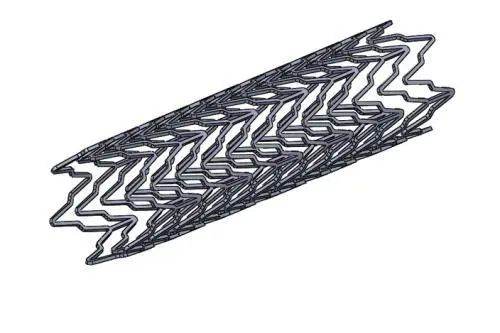

3 Ni-Ti shape memory alloy implant

Transition nickel-titanium alloy has rich phase phenomena, unique morphological effects, excellent mechanical properties, high damping properties and elastic modulus similar to human bone. It is widely used in dentistry, orthopedics, interventional therapy, cardiology, otolaryngology, gynecology and other medical fields, and has become the most promising material for biomedical materials. However, the surface of NiTi alloy implants is prone to induce thrombosis, which is one of the main challenges in its clinical application, and its corrosion resistance and wear resistance are not up to the ideal standard. The release of nickel ions around the tissue after implantation of NiTi alloy may cause allergic reactions and toxic side effects.

Tantalum (Ta) coating: Some researchers have improved the corrosion resistance and barrier effect of the tantalum coating, preventing the release of Ni ions into the immersion solution. A new tantalum coating was prepared on the surface of NiTi alloy, which effectively inhibited the release of Ni ions and effectively improved the radiation opacity of NiTi alloy. The results show that tantalum coating can effectively inhibit the release of Ni ions, and annealing treatment can further reduce the release of Ni ions. Yin et al. formed tantalum coating on the surface of NiTi shape memory alloy (NiTiSMA), which effectively improved the corrosion resistance of NiTi shape memory alloy. The tantalum plating layer is uniform and dense, with a thickness of about 400 μ m。 Electrochemical experiments show that the surface modification can effectively improve the corrosion resistance of NiTi shape memory alloy without galvanic corrosion, which provides a basis for the optimization of NiTi shape memory alloy implants.

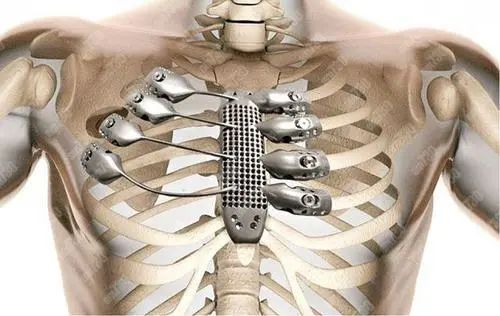

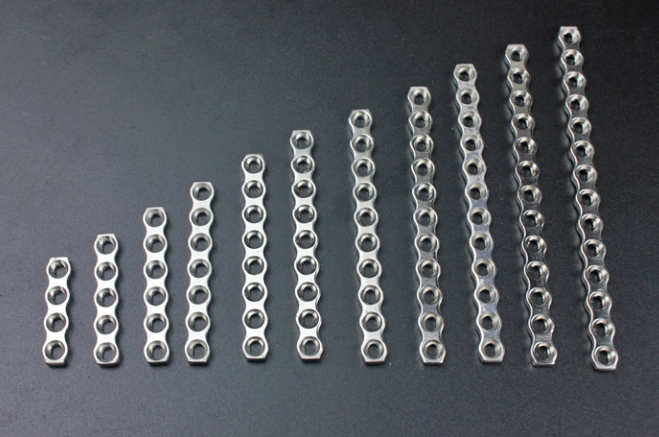

4 Medical stainless steel implants

Medical stainless steel is cheap and easy to process. It has excellent comprehensive performance. However, as an implant, such as artificial joint and clavicle plate, it is easy to be corroded and worn in the body fluid environment, resulting in accelerated deterioration of surface performance.

Tantalum (Ta) coating: Macionczyk et al. believed that ceramic coating, such as TiN or DLC film, is very brittle and usually cannot withstand the plastic deformation of the matrix without cracking or delamination. They prepared a sandwich coating made of tantalum and tantalum oxide to achieve the passive surface of the implant after plastic deformation. The biocompatibility is obtained from tantalum oxide, and the ductility is achieved through the tantalum interface, while ensuring the continuous adhesion of the film, even after the plastic deformation of the steel substrate. The heart-ovate stent with stainless steel - tantalum - stainless steel composite structure can be successfully implanted into human body. Clinical experiments show that the composite structure is harmless and has good development effect.

5 Outlook

The biocompatibility of the coating is the prerequisite for its application in medical devices. In particular, the biocompatibility and related quality of implanted devices are directly related to the life safety of patients, and they need to undergo strict biological evaluation.

The excellent biocompatibility of tantalum metal will bring new hope to common medical device materials. The ion thermal evaporation technology developed by Aines has successfully prepared tantalum coating on medical implant materials such as medical stainless steel, titanium alloy clavicular plate, titanium alloy pad and dental implant, and has been successfully applied in biological experiments. It is believed that with the deepening of research, the tantalum coating technology of Aines will shine brightly in the application of medical device coating.