1 Relevant research

Steegm ü ller R. and colleagues fixed tantalum and gold and marked platinum on the Ni-Ti alloy bracket by laser micro-welding. They place them on the support brace. After laser welding, corrosion experiments were carried out. The results showed that holes (pitting marks) were formed on the platinum marking bracket. They concluded that the gold and platinum markers were very good, but these markers damaged the corrosion resistance of the substrate.

Scott H. put forward a ring mark in his patent, which can be placed on the near end and the far end of the bracket brace. The mark can be fixed by riveting in the hole formed in the support strut/support. The base materials may be platinum and tantalum.

Siekmeyer G. and colleagues compared the characteristics of nickel-titanium stent and marker in their research. The above marks are riveted and micro-welded. The materials marked are gold and tantalum. The analysis is based on scanning electron microscope images, mechanical voltage and corrosion inspection. However, the technical disadvantage used in marking is that it causes seams. This uneven surface leads to greater risks in the implantation process through riveting compared with the marker. In spite of this, the risk of micro-cracks on the support is greater when the rivets are marked during manufacturing.

Stinson S. J. introduced the manufacturing method of metal matrix composite support technology in his patent. He made the tube base material of the support using laser powder scattering technology. He tubes the metal matrix composite into a cylindrical base material, and takes it out of the tube to complete the process by chemical etching, ignition or other mechanical means. Then, the pipe forms a support and is cut by laser. The basic material used for components may be tantalum, niobium, gold, tungsten, ha, palladium or rhodium.

2 Relevant experiments

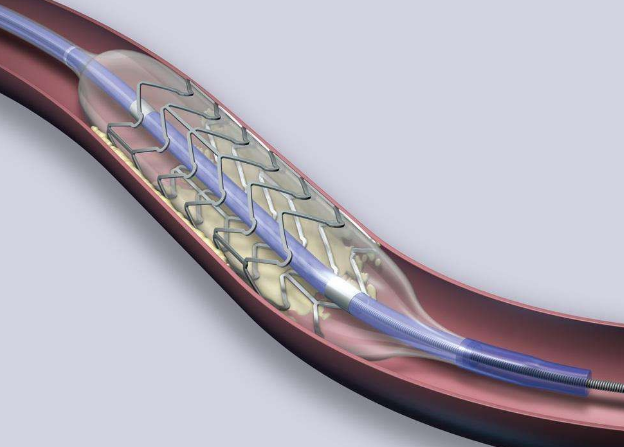

During stent implantation, in order to help doctors use X-ray imaging, some researchers decided to use tantalum metal as a unique marker of cardiovascular stent to increase the X-ray absorption capacity of the stent.

01 Material:

Tantalum (Ta) is a metal material with high hardness and high density, and its physical properties are stable. Tantalum has excellent chemical properties and good corrosion resistance. At normal temperature, it does not react with hydrochloric acid, concentrated nitric acid and "aqua regia". It is known as cermet. Scholars have found that tantalum metal has almost perfect biocompatibility, and its clinical effect is excellent after applying it to clinic.

02 The research contents are as follows:

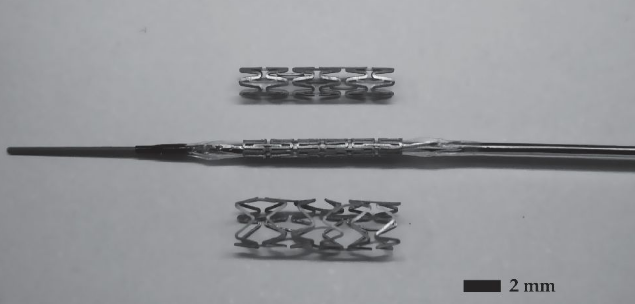

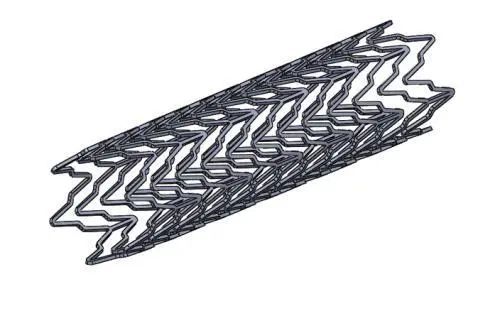

(1) Material: tantalum powder (98% purity and 3-10 µ m grain diameter) is used as the integrated marker of the scaffold. The support is 1.81 mm laser cut outer diameter stainless steel pipe.

(2) Marking method: integrated marking is made by laser ablation, micro-welding and cutting.

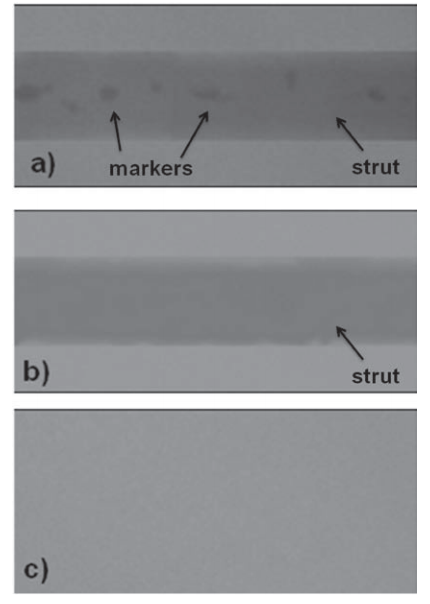

(3) Verification method: compare the markers and create a new analysis method, which can be used to analyze the volume of the integrated markers of the scaffold.

(4) Results: Tantalum powder can increase the local X-ray visibility of the stent to 0.73%.

a) Integrated support marker b) support brace without marker c) background without sample

03 Experimental conclusion:

The use of laser micro-welding, so-called stent integration, can create markers to increase the X-ray visibility of the stent. The new measurement method we described earlier has worked. By analyzing the X-ray micrograph, we can determine the number of stent integrated markers.

3 Epilogue

By comparing the X-ray visibility of the brackets with and without marks, determine the number of marks that can be marked to improve the X-ray visibility. Further, we can consider producing a large number of supports with integrated marks for more research, and use this measurement method to apply to a large number of support types.

AINS focuses on the processing and development of tantalum and niobium products. The existing technology has been applied to the support products. If you have any demand, please consult.